3D Printing updates

Background

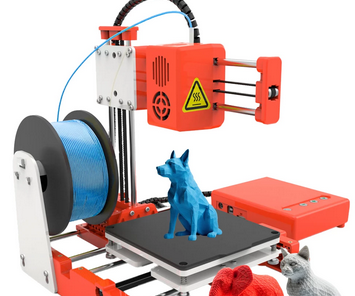

So I am back at playing with 3D printing.

What happened is that I am trying to add a serial port to my QNAP TS-251D NAS which uses a special "flat" low-profile bracket. Since there a none of those available in the open market, I decided to 3D print a bracket.

I was able to find a 3D model for a QNAP TS-563 PCI Bracket for AMD R7 250 Video Card PCIe, which I modified to allow for a DB9 serial port opening.

Also found a local 3D Priting service which lets me upload a model, select different config settings. They would then (for fee) print it and ship it to you.

So far the service is fairly quick and seems reliable so far.

The challenge has been the first few tries did not provide enough structural integrity for it to work. Specifically, it would bend when pushing in the serial port connector so it wouldn't set properly.

Currently I am trying modifying the shape so it bends less easily with a stronger material. Also relocated the port location so it is closer to the edge so it benefits of the support provided by the mounting screw.

The 3D Printing service I am using let's you choose the printing material among the following:

PLA (Polylactic Acid)

What do you use PLA for?

PLA is ideal for projects with limited structural requirements, such as decorative objects or small gadgets.

What are the properties of PLA?

-

Biodegradable and compostable.

-

Made from renewable resources such as corn starch or sugar cane.

-

Has a relatively low melting temperature.

-

Possesses a glossy surface, which makes it attractive for visual applications.

-

For which projects do I use PLA?

Beginner projects, decorative objects, prototypes that do not require high heat or impact resistance.

PETG (Polyethylene Terephthalate Glycol)

What do you use PETG for?

PETG is suitable for projects that require durability, such as functional parts or waterproof objects.

What are the properties of PETG?

- Strong and reliable for long-term use.

- Resistant to many chemicals.

- Suitable for humid environments.

For which projects do I use PETG?

Functional parts, parts that are used outdoors, or objects that require some flexibility and strength.

TPU (Thermoplastic Polyurethane)

What do you use TPU for?

TPU is suitable for flexible and durable projects, such as phone cases, flexible hinges or shock-absorbing parts.

What are the properties of TPU?

- Ideal for flexible objects.

- Excellent wear resistance.

- Provides good protection against shocks.

- Resists oil, grease, and more.

For which projects do I use TPU?

Phone cases, hinges, shoe soles, and other products that require flexibility and durability.

ABS (Acrylonitrile Butadiene Styrene)

What do you use ABS for?

ABS is used for projects that require strength and heat resistance, such as mechanical parts or housings.

What are the properties of ABS?

- ABS is strong and tough, suitable for solid objects.

- Can withstand higher temperatures than many other plastics.

- Can be sanded, drilled and painted for various finishes.

For which projects do I use ABS?

Functional prototypes, tools, and parts for the automotive industry

ASA (Acrylonitrile Styrene Acrylate)

What do you use ASA for?

ASA is ideal for outdoor applications that require UV resistance and weather resistance, such as automotive parts or outdoor decorations.

What are the properties of ASA?

- ASA does not fade under exposure to sunlight.

- Resistant to water and many weather influences.

- Provides a strong and durable finish.

For which projects do I use ASA?

Outdoor projects, parts for cars or garden furniture, and any object exposed to the elements.

PA-CF (Polyamide Carbon Fiber)

What do you use PA-CF for?

PA-CF is used for highly load-bearing applications that require stiffness and wear resistance, such as industrial tools or parts with high mechanical loads.

What are the properties of PA-CF?

- PA-CF provides exceptional stiffness for precision parts.

- Highly resistant to wear, ideal for moving parts.

- Retains properties at higher temperatures.

- Good resistance to many chemicals and solvents.

For which projects do I use PA-CF?

Aerospace, automotive, and mechanical engineering, where parts must be able to withstand high temperatures and wear.

For the bracket I am using PA-CF as it seems to be the most rigid material I have tried so far.